Spray Dryer

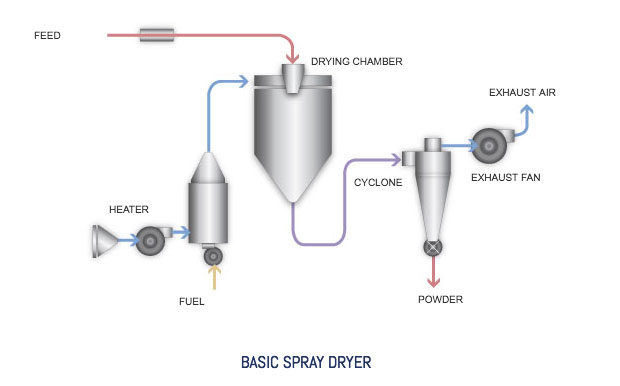

Spray drying is the most widely used industrial technology for obtaining powdered solids from a liquid feed. The solution, suspension or emulsion is atomized into a spray of very small droplets that are mixed with a hot air flow inside a drying chamber. The drying process of those droplets forms small particles with very little moisture content that may or may not agglomerate inside the same drying chamber.

A spray dryer allows drying of heat sensitive products, because of the short residence times and low temperatures inside the chamber.

Our knowledge of spray drying technology allows us to offer drying plants with different arrangements depending on the product, the properties of the liquid feed and the desired properties of the powder.

Among the alternatives we offer you can find:

- Atomization through nozzles or rotary disc

- Co-current, counter-current or mixed air flow

- Single and multiple stage drying

- Air or inert drying gas in open, semi-closed or fully closed circuit

- Direct or indirect air heater

- Fines return system for agglomeration

Atomizing Method

Spray drying chambers have different means of atomizing the feed to guarantee the size and uniformity of the generated droplets. Two alternative systems are used to achieve this, either with a rotary disc atomizer or through atomizing nozzles.

Spray dryers with rotary disc atomizer have more flexibility regarding feed flow rate, but the droplets formed are not of similar size while spraying nozzles are more demanding on a precise flow rate but they form similar size droplets which helps controlling the drying process and the final product.

Booth systems can be used in most applications and a case-by-case analysis must be made to determine the most adequate method.

Drying Air Flow

An important factor when building spray dryers is to determine how will the drying air flow through the chamber. Depending on the type of drying chamber, product and other parameters, air can flow in a co-current, counter-current or mixed fashion. Most dryers use co-current air flow in which the air and product enter the chamber through the top, because this way the air at high temperature coming from the hot air generator mixes with the product with the highest water content. The water evaporating from the product acts as a temperature buffer both avoiding the product to reach high temperatures and at the same time cooling the hot air very quickly due to the drying process. Product and air exit the chamber through the bottom. This arrangement is very suitable for heat sensitive products.

Counter current flow means the air enters through the bottom and the product through the top. Product is discharged through the bottom and air and discharged through the top.

In mixed air flow spray dryers hot air enters both from the top and bottom at the same time while the product enters through the top. Product is discharged through the bottom and both air flows exit through the top.

Multiple Stafe Spray Drying

Spray dryers can have one, two or three stages, resulting in agglomerated products and reducing drying energy costs.

In one stage spray dryers, the product is involved in only one process that reduces its water content up to the desired percentage, after which it is separated from the air flow that carries it. These drying chambers usually render a product of small particle size, similar to a fine powder and, depending on the product, with a limited rehydration capability because of the discrete and compact particles formed. The initial investment required for these kind of spray dryers is the lowest in comparison to other alternatives.

In a two stage spray dryer, the product exiting the chamber is sent to an external vibrating fluid bed dryer. The moisture when exiting the drying chamber is not the required final humidity for the product, but slightly higher, passing through an extra drying process in the fluid bed dryer. Construction specifications are similar than for a one stage chamber, but operating conditions change (exit product moisture, air temperatures, flow rate and other parameters).

A three stage spray dryer requires a chamber with a different design than a one or two stage dryer. These kind of chambers have an internal static fluid bed dryer at the base and an external vibrating fluid bed dryer also. The product passes through 3 drying processes. The main process occurs in the drying chamber, where product is dried up to 12-15% of water content. Then it is lowered to around 5-6 % in the internal static fluid bed, where air flow is independent from the one in the chamber, allowing fine temperature control for the air in contact with an almost dry product and is very appropriate for heat sensitive products. Agglomeration takes place here, favoring rehydration of the product. This is wanted for products like milk poder and instant coffee.

In the external fluid bed the product is dried to the final moisture content, usually with one or two independent hot air flows and then a cold air flow cools the product down to the appropriate packaging temperature, avoiding lumps to form in its final package.

Closed Cycled Drying

In certain drying processes, oxygen content in the system is no desirable due to the formation of by product or for the risk of explosion when handling highly flammable products. This is why SEI Contreras Engineering has the technology, know-how and experience to design and build spray drying systems that use air or an inert gas (N2, CO2) in semi-closed or fully closed circuits. This way, oxigen content in the drying air is lowered while reducing the emmision of hazardous gaseous components to a minimum.

Hot Air Generation

Hot air generation for spray dryers can be of two types: direct or indirect.

In a direct system the heated air is mixed with the combustion gasses in the correct proportion to achieve the required flow rate and temperature. This mix is used in the spray dryer and has direct contact with the product. This is why for certain food products and indirect heating method is used. In these kind of heaters the combustion gasses do not have direct contact with the drying air because an indirect heat exchanger avoid mixing of both currents.

Fines Return System

One of the most wanted properties of powdered products is their rehydration capacity. This can be achieved by choosing the adequate spray drying chamber and with the addition of external equipments.

A fines return system that facilitates agglomeration inside the chamber results in a high dispersability product. This can be achieved recirculating a portion of the generated powder back to the chamber. When this powder contacts the droplets from the rotor atomizer or nozzles a partial agglomeration of the particles is produced, forming a large number very small cavities when evaporation occurs. These spaces increase water-particle contact area when rehydrating. In the internal fluid bed this agglomeration is completed by the semi-dry intense contact.

Another alternative that can be used to increase dispersability of the product, specially for products with a certain fat content, is the use of lecithin by means of a very fine spray of lecithin solution.

Additional Equipment

- Pneumatic transport systems for dried product

- Preheaters for feedstock

- Gas Scrubbers

- CIP Cleanable Tangencial Bag Filter