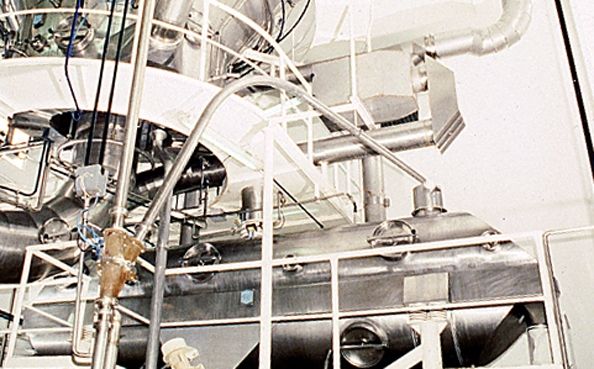

Vibrating Fluid Bed Dryer

SEI Contreras Engineering has provided many types of dryers over its more forty years of existence.

One of the most commonly used dryers for powder processing are vibrating fluid bed dryers. These equipments can be used as a stand-alone dryer in many processes, although they are normally used as finishers after a spray dryer.

A vibrating fluid bed dryer has a closed and cylindrical horizontal body where the product enters through one end and exists from the opposite. Inside this cylinder there is a horizontal perforated sheet that acts as a supporting base where the product flows. Through the holes of this sheet the drying air flows upwards through the product, keeping it suspended and free flowing towards the exit. The thickness of the suspended product layer should not be over 15 cm (6 inches), given that thicker layers are harder to keep in suspension, pressure loss in the drying air is high and an even product is harder to obtain.

Vibrating fluid bed dryers can have many sections or stages, and it is common to find two drying stages at different temperature and a cooling stage in which the product reaches an adequate temperature for packaging or storage.

To increase heat transfer and homogeneisation of the product while improving their flow inside the equipment, eccentric motovibrators are used. The whole dryer is supported by shock-absorbers and the movement of the vibrators results in a high frequency vibration that removes the product inside it which combined with the effect of the drying air through the perforated sheet helps keep the product suspended and adequately mixed.